Detailed description

Achieve precise and efficient wire stripping with our premium-quality wire stripping blades. Crafted from high-grade materials and manufactured with exceptional accuracy, our blades are designed to enhance your wire processing operations.

Uncompromising Material Quality:

Our wire stripping blades are manufactured using high-quality tungsten steel or high-speed steel, ensuring exceptional durability and cutting performance. We also offer customizable material options to meet specific application requirements. Please let us know your needs, and we will tailor the blade material accordingly.

Enhanced Durability through Vacuum Heat Treatment:

All our wire stripping blades undergo a rigorous vacuum heat treatment process. This critical step effectively eliminates internal stress within the steel, significantly improving the blade's punching ability and extending its lifespan. You can rely on our blades for consistent performance even under demanding conditions.

Precision Manufacturing for Optimal Performance:

The cutter body of each blade is meticulously processed using a high-precision grinding machine, ensuring accurate dimensions and a smooth finish. The cutting edge is then crafted with utmost precision using an advanced CNC slow wire cutting machine, achieving an impressive accuracy of ±0.001mm. This level of precision guarantees clean and accurate wire stripping every time, minimizing damage to the conductor.

Stringent Quality Control with Computer Projector Testing:

To ensure the highest standards of quality, all our wire stripping blades are subjected to thorough testing using a computer projector. This advanced quality control method allows us to verify the accuracy of the blade dimensions and cutting edge, guaranteeing that each blade meets our strict specifications.

Wide Applications Across Industries:

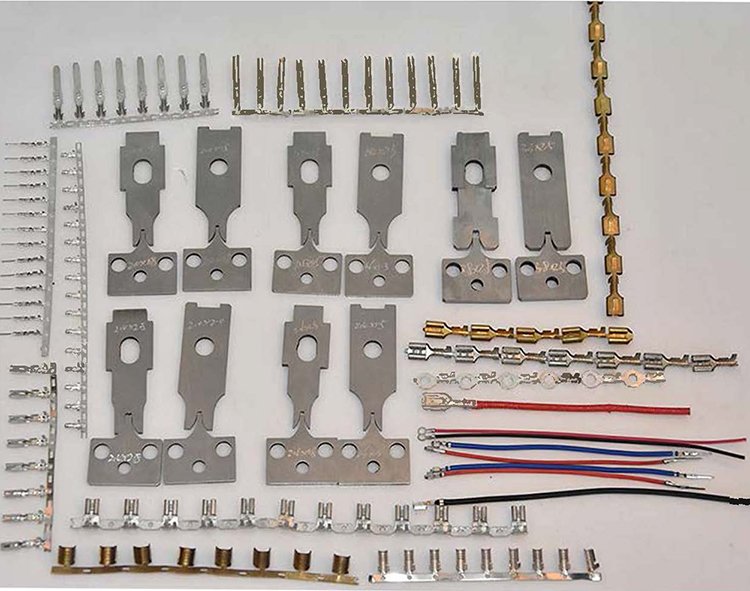

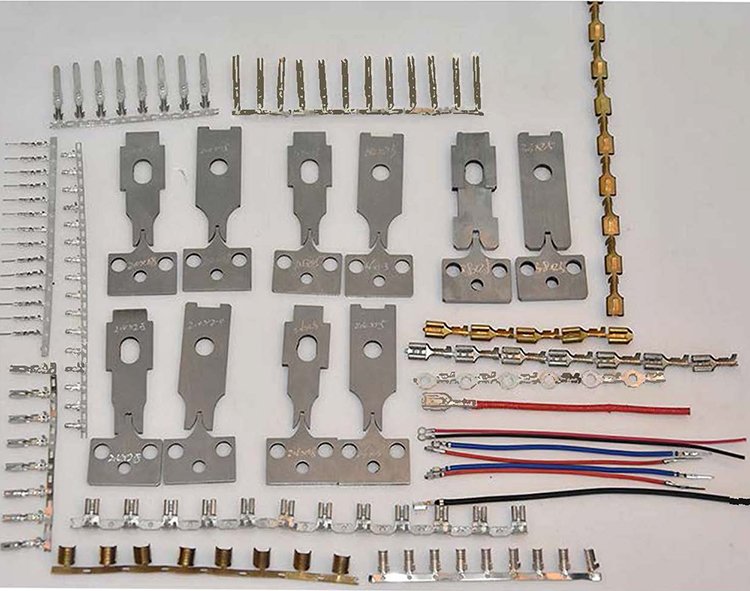

Our tungsten steel knives are widely utilized in various industries, including:

-

Electronic Wire Processing Industry: For precise stripping of delicate electronic wires.

-

Machinery Industry: For stripping wires used in various mechanical applications.

-

Terminals Industry: For preparing wires for terminal crimping.

By using our high-quality wire stripping blades, you can significantly improve production efficiency and ensure consistent, reliable results.

Comprehensive Customization Services for All Your Needs:

We understand that different applications require specific tools. That's why we offer comprehensive customization services for various types of blades:

-

Customize all Wire Stripping Blades: Tailor the blade design and dimensions to your exact wire stripping needs.

-

Customize all Pneumatic Stripping Machine Blades: Create specialized blades for your pneumatic wire stripping equipment.

-

Customize all Terminal Crimping Machine Blades: Design custom blades for precise terminal crimping applications.

To initiate the customization process, simply provide us with your technical drawings or samples. Our experienced engineers will work with you to create the perfect blade for your specific application.

Easy and Transparent Shopping Process:

We have streamlined our ordering process to make it as convenient as possible for you:

First Step: Send clear pictures and drawings of the blade you require to our customer service team.

Second Step: Our dedicated representatives, Lily or Vera, will communicate with you to determine if it's necessary for you to send blade samples or terminal and wire samples to us for accurate customization.

Third Step: We will provide you with a detailed quotation including the price and estimated delivery time for your order.

Fourth Step: Once you approve the quote and make the payment, we will immediately begin the customization process for your blades.

Fifth Step: After the blades are manufactured, we will send you pictures or a video showcasing the blade's performance, awaiting your confirmation.

Sixth Step: Upon your confirmation that everything is satisfactory, we will carefully pack and ship your customized wire stripping blades.

Choose Our Wire Stripping Blades for:

-

Superior Material Quality: Tungsten steel, high-speed steel, and customizable options.

-

Enhanced Durability: Vacuum heat treatment for increased punching ability.

-

Unmatched Precision: High-precision grinding and CNC slow wire cutting.

-

Rigorous Quality Control: 100% testing with computer projector.

-

Wide Range of Applications: Suitable for various industries.

-

Comprehensive Customization: Tailored blades for all your stripping and crimping needs.

-

Easy and Transparent Ordering Process: Clear steps from inquiry to shipment.

Start your wire stripping blade customization journey today! Send us your blade pictures and drawings to our customer service team to begin the process.

Keywords for Google Search: Wire stripping blades, tungsten steel blades, high-speed steel blades, custom wire stripping blades, pneumatic stripping machine blades, terminal crimping machine blades, vacuum heat treated blades, precision wire stripping blades, CNC wire cutting blades, wire processing blades, electronic wire stripping blades, machinery wire stripping blades, terminals industry blades, wire stripping tool, wire preparation blades.