Main Accessories:

-

Cylinder: Yadeke cylinder and solenoid valve

-

Winding Main Servo Motor: 1000W Turbot

-

Take Line Translation Servo Motor: Turbot 1500W

-

Linear Motor Module Shift Servo Motor: Turbot 750W

-

Online Translation Servo Motor: Dongling 750W

-

Up and Down Servo Motor: Dangling 750W

-

Winding Up and Down Motor: 57 closed-loop Mine Race

-

Twisting and Strapping Belt Spitting Belt Motor: 57 stepper motor Thunder Race

-

Storage Tape Motor: 6W

-

Slide Block: Take line translation double slide block linear motor module

-

Guide Rail: Lower paw translation double guide rail

-

PLC: Vigor

-

Screen: Dimension control 7"

-

Power Supply: Clear Weft

-

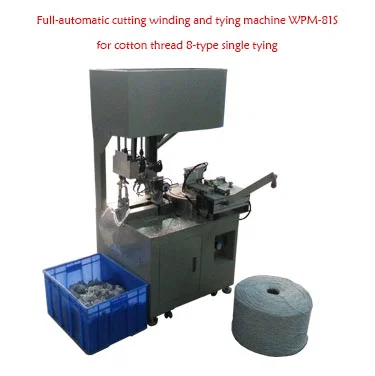

Frame: Iron frame, painted blue and white

-

Safety Protection: Stop when the door opens

-

Lack of Material Alarm: Three-color lamp buzzes

Ideal for High-Quality Wire Manufacturers:

The WPM-CPRT81TH is specifically designed for high-quality wire manufacturers dealing with wire harnesses, hoses, and ropes that require precise meter cutting, stripping, and 8-figure single tie winding.

Maximize Efficiency and Product Quality:

Invest in the WPM-CPRT81TH to significantly enhance your production efficiency, ensure exceptional product quality, reduce labor costs, and achieve perfectly formed and tied 8-figure wire bundles.

Contact us today for a detailed quote and to discover how the WPM-CPRT81TH can revolutionize your wire processing operations!

Keywords for Google Search: High-end meter precision cutting winding tying machine, big 8-word tie machine, automatic wire cutting machine, automatic wire stripping machine, wire harness machine, WPM-CPRT81TH, precise wire processing, servo motor wire winding, automatic cable cutting stripping winding tying, 8-figure winding machine, wire harness manufacturing equipment.