Detailed description

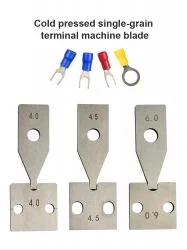

Maximize your wire stripping efficiency and precision with our premium-quality wire stripping blades, expertly crafted from Tungsten Carbide and High-Speed Steel (HSS). Engineered for exceptional hardness, wear resistance, and longevity, our blades are the ideal choice for high-speed and automated wire processing.

Superior Blade Materials:

We offer wire stripping blades made from two primary high-performance materials:

-

Tungsten Carbide: Renowned for its exceptional hardness, superior wear resistance, and ability to maintain a sharp cutting edge for extended periods. This material is highly recommended for demanding applications and high-speed wire stripping.

-

HSS (High-Speed Steel): Offers a good balance of hardness and toughness, providing reliable performance for a wide range of wire stripping tasks.

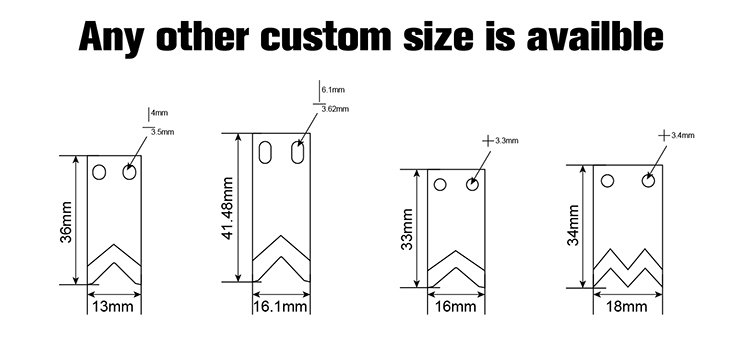

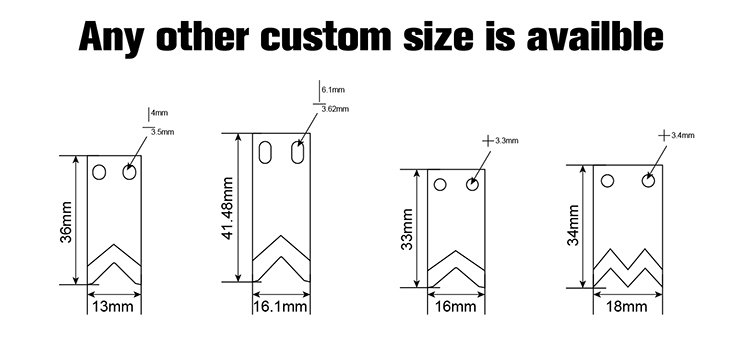

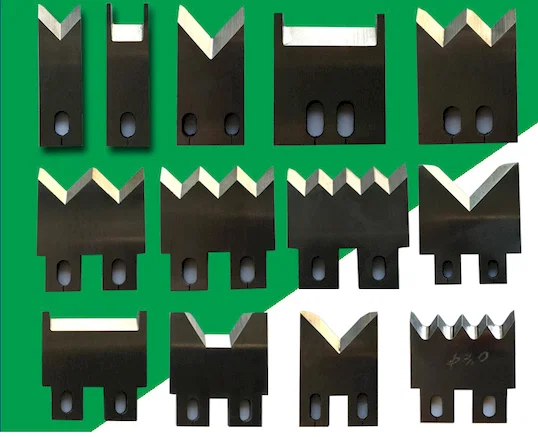

Standard and Customizable Blade Sizes & Shapes:

Our standard blade sizes include:

-

36mm x 15mm x 2.5mm

-

34mm x 18mm x 2.5mm

Beyond these standard dimensions, we understand that different applications have unique requirements. We offer customization services for both standard and irregular blade shapes. Simply provide us with your specific dimensions or technical drawings, and our skilled technicians will manufacture blades to your exact specifications.

Key Properties and Advantages:

-

High Hardness: Ensures clean and precise stripping, even on tough insulation materials.

-

Exceptional Wear Resistance: Provides a significantly longer lifespan compared to blades made from other materials, reducing replacement frequency and downtime.

-

Longer Life: Minimizes the need for frequent blade changes, saving you time and money.

-

Sharper Cutting Edge: Delivers consistent and efficient stripping performance.

-

Drawing or Specification Customization Accepted: We can manufacture blades to your exact requirements.

The Importance of Material Selection for Optimal Wire Stripping:

The process of wire stripping often involves materials with high hardness, and wire stripping machines operate at extremely high speeds. Therefore, the wire stripping blades must possess exceptional hardness and outstanding wear resistance.

While HSS is a common material for wire stripping blades, Tungsten Carbide is the strongly suggested material for achieving superior cutting performance. This is due to its remarkable combination of:

-

High Hardness: Enables clean and effortless cutting of various insulation types.

-

Excellent Wear Resistance: Ensures a prolonged blade lifespan, even in high-throughput environments.

-

High Strength and Toughness: Provides resistance to chipping and breakage under demanding conditions.

-

Favorable Heat Resistance: Maintains cutting performance even at elevated operating temperatures (up to 500°C or 1000°C).

-

Corrosion Resistance: Enhances the blade's durability and longevity.

As a result of these excellent properties, a Tungsten Carbide wire stripping blade is highly recommended as your first choice for achieving optimal and consistent wire stripping results.

Maximize Efficiency and Reduce Costs:

Our skilled processing technology ensures an extended blade lifetime, leading to improved equipment efficiency and increased production output. Furthermore, by using our high-quality blades, you can significantly reduce the frequency of blade changes and save valuable time spent on adjusting machine pressure due to worn-out blades.

Find the Perfect Blades for Your Machines:

Our wire stripping blades are compatible with a wide range of wire stripping equipment, including:

-

Various High-Speed Wire Stripping Machines

-

Automatic Wire Stripping Machines

-

Pneumatic Wire Stripping Machines

-

And more.

Optimize your wire processing operations with our high-performance Tungsten Carbide and HSS wire stripping blades. Contact us today with your specifications or drawings for a customized solution tailored to your exact needs.

Keywords for Google Search: Wire stripping blades, tungsten carbide blades, HSS blades, high-speed steel blades, automatic wire stripping machine blades, pneumatic wire stripping machine blades, custom wire stripping blades, blade customization, wire processing blades, high hardness blades, wear resistant blades, long life blades, sharp wire stripping blades, 36152.5mm blades, 34182.5mm blades.

Find the blades here For various high-speed wire stripping machines, automatic wire stripping machines, pneumatic wire stripping machines, etc.